If you’ve ever stared at a pile of drone parts wondering what screws fit DJI mini motors, you’re not alone. The question pops up often because these compact brushless units aren’t meant for tinkering—yet builders keep finding clever ways to repurpose them. In the next hour, you can identify your motor’s thread size, grab compatible screws from your bench stash, and test-fit them safely without stripping aluminum threads.

Why tinker with DJI Mini Motors now?

DJI’s lightweight “Mini” line—especially the Mini 3 Pro—has made sub‑250 g flight suddenly practical for serious experiments. Builders are pulling these tiny powerhouses off crashed or retired drones to power micro‑VTOL wings or fixed‑wing conversions. Unlike open‑source racing motors with standard M2 mounts, DJI’s proprietary screws keep people guessing. That gap between curiosity and specification is where hobbyists have started reverse‑engineering—and sharing their findings—to make those reused components viable again.

How the mounting setup works on DJI mini motors

Here’s a quick do‑this‑then‑that list to confirm what you have and how to attach it securely:

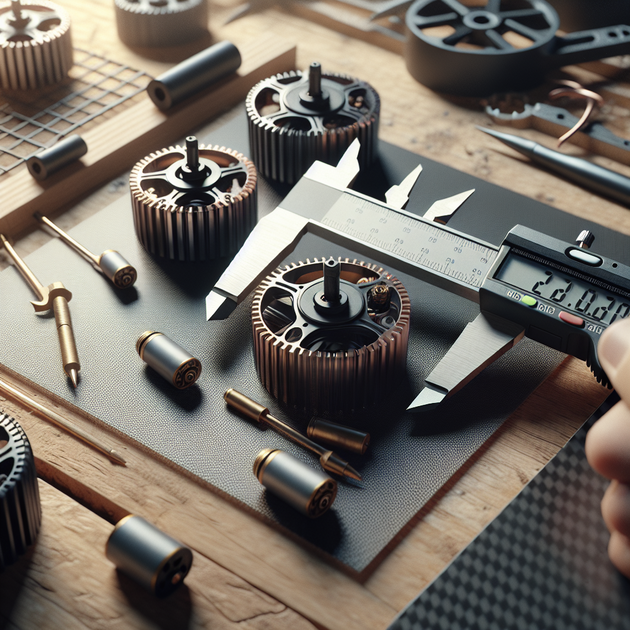

- Step 1: Flip the motor upside down on a soft cloth. Locate the three bottom holes around the bearing housing—these are your mounting points.

- Step 2: Use a digital caliper to measure the thread diameter. Expect roughly 1.4–1.6 mm; if your M1.5 gauge pin fits snugly but not tight, it’s likely M1.6.

- Step 3: Check thread pitch with a screw gauge or by gently threading an M1.6×3 mm stainless bolt by hand. If resistance kicks in early, back out immediately; DJI aluminum is soft.

- Step 4: Align the motor on your frame template or carbon plate. Mark hole centers with a fine tip marker through each mount hole; drill only once confirmed symmetrical.

- Step 5: Test fit all three screws equally before tightening any single one—hand torque first, then light driver torque (<0.2 N·m). Verify free motor spin afterward.

This method avoids over‑tightening while confirming both pitch and alignment before power tests.

Field note from a garage builder

A pilot named Chi shared online that they were building a sub‑250 g VTOL wing using reclaimed Mini 3 Pro motors but couldn’t identify the screw size—thought it might be M1.5 but wasn’t sure. That uncertainty is exactly what stalls many home builds mid‑weekend: one missing measurement means everything sits half‑assembled on the workbench until new bolts arrive.

I’ve seen similar scenes in maker labs—the moment someone thinks they’ve got “close enough” hardware from an RC car kit and it almost fits… until one screw cross‑threads and ruins a $30 motor baseplate. The trick isn’t brute force; it’s patience with measuring tools that cost less than those stripped parts.

Contrarian insight: sometimes reusing isn’t cheaper

The romantic idea of upcycling branded components often clashes with reality. DJI doesn’t publish mechanical specs for its proprietary parts because they’re designed as integrated systems—not modular kits. That means you spend time decoding thread sizes that could’ve gone into flight tuning or firmware testing.

The contrarian takeaway? Sometimes buying open‑standard brushless motors (e.g., 1103–1204 series) saves both time and nerves when you factor in custom adapter plates and trial bolts. However, if stealth efficiency or noise reduction from DJI rotors matters more than simplicity, then yes—hacking these parts pays off in performance per gram.

Common pitfalls when working with DJI mini motors

The biggest trap is assuming the threads follow common metric patterns. They’re close but not identical to hobby store stock screws. Another issue is screw length—anything beyond 3 mm risks contacting stator windings inside the bell housing.

Avoid this:

- Never use self‑tapping or coarse‑thread “micro wood” screws; they cut new threads into aluminum and destroy precision balance.

- If unsure about depth, insert a toothpick until it stops at internal metal; mark it with tape and measure outside length—that’s your safe screw limit minus 0.5 mm clearance.

- Tiny washers help distribute pressure if your frame holes aren’t perfectly flat; otherwise torque shifts during vibration tests can loosen one corner first.

A little prep here saves hours diagnosing why one motor vibrates under throttle even though your PID tune looks fine.

Quick sanity checks before flight

Once mounted:

- Spin each motor by hand; feel for drag or clicking—any roughness means misalignment or bent shaft.

- Check continuity between screw heads and motor leads using a multimeter; zero reading means no shorts to windings.

- Power up slowly under ESC calibration mode (throttle min → max → min). Listen for balanced whine across all units within ±100 RPM difference at idle.

If anything feels off—stop there. Revisit mounting symmetry rather than forcing trim in software later.

Edge case: temperature drift on reused stators

When salvaging from crashed Minis, watch out for heat fatigue on stator enamel coating. Motors that ran hot before impact might still spin fine unloaded but fail under sustained current draw after rebuilds. A quick IR thermometer scan (20 s hover test) reveals hotspots over 70 °C—replace those units immediately or risk ESC desync mid‑air.

Quick wins for anyone experimenting

- Label everything: Use masking tape tags (“front left”, “rear right”) before wiring—it halves later debugging time.

- Create a screw test card: Keep sample bolts taped beside caliper notes so future builds start faster.

- Add Loctite 222 (purple): Only minimal amount; blue formula is too strong for M1.x threads.

- Print a motor spacer ring: A 0.5 mm nylon shim between frame and motor base improves cooling airflow on tight mounts.

- Tighten diagonally: Quarter‑turn pattern maintains even compression across fragile mounts.

The pragmatic wrap-up

Treat every reclaimed Mini component like lab equipment rather than spare junk—it rewards care with quiet precision flight later. Knowing how those hidden fasteners behave turns guesswork into repeatable engineering steps rather than weekend frustration.

The real advantage isn’t just saving money—it’s learning mechanical empathy at micro scale: feeling torque through fingertips instead of relying on spec sheets that don’t exist publicly. That’s what separates casual part swappers from genuine builders who iterate toward lighter airframes without sacrificing reliability.

You can start tonight by measuring one of your spare Mini motors under magnification and noting dimensions in your build log. That simple act converts mystery into data—the first step toward any controlled experiment in DIY aviation.

Your turn

If you had one salvaged Mini motor sitting on your desk right now, would you try to fit it onto a new frame—or design around its quirks entirely?

By Blog-Tec Staff — edited for clarity.

Leave a Reply