Sometimes the best trunk repair ideas cost almost nothing and take less time than brewing coffee. That’s exactly what happened when one driver found a quick fix by 3D printing a drain plug for their vehicle’s trunk—spending only two cents and five minutes.

Why Quick Trunk Repair Solutions Matter

A small hole in your car’s trunk might seem minor, but it can cause more trouble than most expect. Water leaks lead to rust and can ruin anything stored there. Traditional repairs often involve adhesives or expensive replacement parts.

With water damage being one of the most common car issues, finding fast and effective solutions is crucial for keeping your vehicle in good shape.

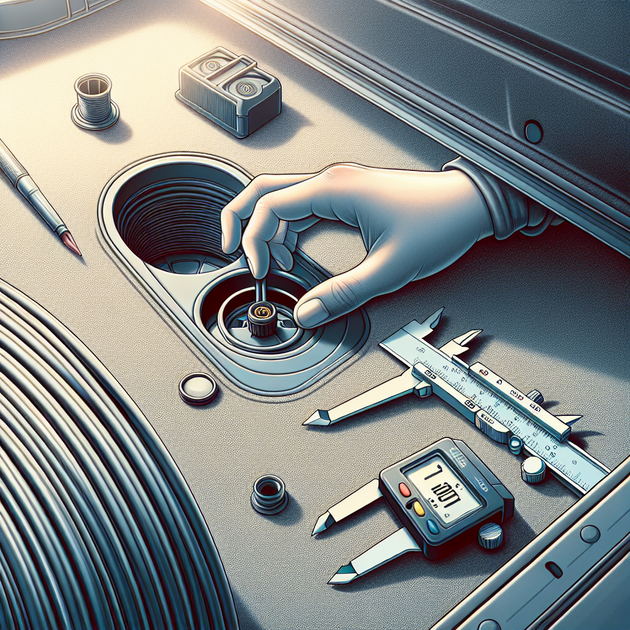

Tools Needed for This DIY Fix

- Digital calipers (for accurate measurements)

- Access to Thingiverse or similar site with printable models

- Basic knowledge of scaling STL files

- 95A TPU filament (flexible and perfect for friction fits)

- A working 3D printer

How the $0.02 Trunk Repair Worked

The process started by searching Thingiverse for an appropriate drain plug model that could fit the size of the trunk hole. After taking quick measurements with calipers, the file scale was tweaked slightly before printing.

The print used some leftover 95A TPU filament—a material known for its flexibility and durability. It’s often recommended by makers for parts needing a snug fit because it resists vibration and seals tight gaps well.

The Steps at a Glance:

- Measure hole diameter with calipers.

- Find or design an STL file of a drain plug (see Printables).

- Edit the scale of the model as needed.

- Print using TPU filament.

- Press-fit into place—no glue needed!

Anecdote: The Satisfaction of Getting It Right First Try

Succeeding on the first print run feels great, especially when using filament that’s been sitting around waiting for its moment to shine. In this case, six-month-old TPU finally found its purpose as the perfect friction-fit plug—no wasted material or failed prototypes.

The fix was secure right away and didn’t require special adhesives or tools beyond what many hobbyists already have at home.

Why Use TPU Filament for Car Repairs?

- Flexibility: Adapts well to irregular holes and seals tightly.

- Toughness: Stands up to vibration and temperature swings (learn more about TPU properties here).

- No residue: Friction fit means no sticky messes or cleanup later.

The Pros of DIY Car Fixes Like This One

- Saves money compared to auto shop visits or OEM parts.

- Makes use of materials you already have on hand.

- Cuts down on wait time—no ordering specialized components online.

Bigger Picture: Is This Approach Right For You?

If you have access to basic measurement tools and a consumer-grade printer, small repairs like this are within reach—even if you’re new to DIY car fixes. The trick is paying attention to detail when measuring and being willing to experiment with scaling models before hitting print.

Bounceback Question

Have you ever used technology like 3D printing to solve an everyday problem? What would you try fixing next with your own tools?

Leave a Reply