If you’ve ever wrestled with fragile LEDs or tangled breadboard wires, you’ll get why people are talking about LED filaments in glass fuses. It’s a clever way to package delicate filament LEDs into sturdy housings that click neatly into holders—something you can actually build within an hour using common bench tools.

What’s New with LED Filaments in Glass Fuses

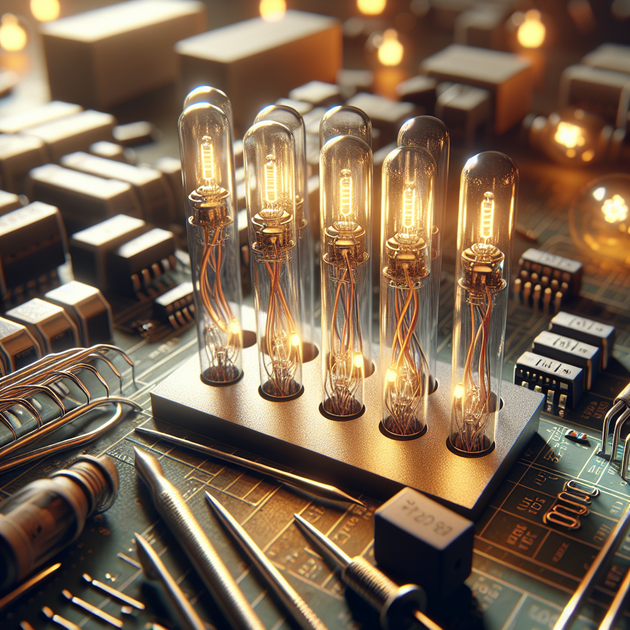

This idea came from a Reddit post by user Ghost1e_1998, who showed off a neat mod where they slid filament-style LEDs into standard 5×20 mm glass fuse shells. The result looks like tiny neon tubes that plug directly into fuse clips. What’s new here isn’t the filament itself—it’s the packaging. Instead of fiddling with bare leads or fragile solder joints, each filament is now sealed and handled like a replaceable component.

That small change matters more than it sounds. Fuse bodies are standardized, cheap, and already have secure contact caps at each end. By reusing that hardware, makers can snap LEDs into sockets built for quick swapping—ideal for prototyping panels or aesthetic lighting arrays.

How It Works — Hands-On Steps

The process looks tricky but breaks down cleanly once you set up your station. Here’s the minimal workflow:

- Step 1: Desolder the metal end caps from a blown 5×20 mm glass fuse. Twist gently; avoid cracking the tube.

- Step 2: Cut your LED filament (commonly from a “COB” style warm-white stick) to fit inside the tube lengthwise.

- Step 3: Solder fine magnet wire to each filament terminal. Check polarity—most filaments are marked or can be tested with a bench supply at 3 V DC.

- Step 4: Slide the wired filament into the cleaned glass body. Apply a dab of clear epoxy at each end before reseating the metal caps.

- Step 5: Let cure 30 minutes; then test continuity using your multimeter on “diode” mode before powering up.

If everything glows evenly at 3–5 V, you’re done. The fuse form keeps things tidy and lets you snap multiple “light capsules” into any inline holder or panel mount socket.

A Quick Shop-Bench Story

I tried this myself last weekend after seeing that Reddit thread blow up overnight. My old breadboard LEDs were dull compared to these slim tubes glowing clean through glass. After finishing three units—cool white, amber, and red—I realized the true perk wasn’t brightness but orderliness. I could swap colors just by pulling one fuse and inserting another. No resoldering, no finger burns.

A friend dropped by mid-test and asked where I bought those “micro neon bulbs.” That’s when it clicked—this trick blurs lines between repair parts and design elements. Something built for circuit protection ends up as an aesthetic light module.

The Subtle Catch — Heat and Voltage Limits

Here’s where pragmatism pays off. These filaments aren’t drop-in replacements for real fuses; they’re decorative or indicator modules only. Run them beyond 5 V or without proper current limiting and they’ll overheat fast inside that sealed glass barrel.

The fix is simple but non‑negotiable:

Add a resistor inline—typically 470 Ω if feeding from 5 V—or use a constant‑current driver rated for under 20 mA per filament segment. Without ventilation holes (you don’t want those anyway), heat accumulates quickly. If you see condensation fogging the tube after a minute of operation, shut down immediately; that means epoxy outgassing or moisture trapped inside.

A more advanced mitigation is to fill one cap end with thermally conductive silicone instead of epoxy; it wicks heat into the metal shell without stressing the glass bond line.

Why This Mod Actually Matters

At first glance this hack seems cosmetic—a fancy housing for an existing light source—but it taps into something deeper about modular design thinking. Electronics work best when components can be replaced without rework. Standard fuse holders are everywhere—from guitar amps to power strips—and by reusing that footprint for LEDs, hobbyists gain an instant infrastructure of sockets and clips already integrated into countless devices.

This crosses from “DIY novelty” to pragmatic engineering because it makes testing indicator lights safer and faster. There’s less chance of accidental shorting while probing live circuits since every contact is enclosed within glass and metal caps rated for electrical isolation.

The contrarian insight here? Sometimes progress comes not from new parts but from reusing obsolete ones smartly. In an age of endless custom PCBs and connectors, adopting legacy hardware like fuse shells feels almost rebellious—and yet perfectly efficient.

Quick Wins If You Want To Try It

- Use standard 5×20 mm fuse holders; avoid odd sizes or ceramic types—they block light entirely.

- Label each unit’s voltage/resistor combo on masking tape before storage; saves confusion later.

- If your epoxy yellows under heat, switch to optical-grade silicone adhesive rated above 120 °C.

- Add small dots of black paint on one cap as polarity markers—helps during quick swaps.

- Keep spare blown fuses; their caps recycle perfectly after desoldering residue tin with wick braid.

Troubleshooting Checklist

If your build doesn’t light up immediately:

– Verify polarity with your power supply set to current limit mode.

– Inspect solder joints through magnification; LED filament pads are fragile.

– Check resistance between caps—it should read open until forward-biased.

– Re‑flow solder quickly; prolonged heat melts glue under the cap.

A small bench microscope helps spot hairline fractures in the glass during assembly—don’t risk high voltages if cracks appear near the edges.

Beyond Hobby Desks — Potential Uses

This concept might migrate beyond personal projects soon. Small‑batch manufacturers experimenting with modular backlighting could adopt similar housings for serviceable indicator banks or prototype panels where visual feedback modules need quick replacement without rewiring harnesses.

An engineer at my local maker space pointed out another angle: museums restoring vintage control boards could use these “fuse LEDs” as reversible replacements for burned‑out neon indicators—keeping authenticity while improving longevity.

Sourcing Parts Without Guesswork

You don’t need specialty suppliers to get started:

– Grab cheap COB filament segments from any generic bulb teardown.

– Save blown glass fuses from scrap boards.

– Use magnet wire salvaged from old headphone coils—it’s thin enough to fit under end caps.

If you prefer verified stock over salvage hunting, check vendors like Mouser Electronics or SparkFun; both carry compatible holders and adhesives suited for low‑voltage builds.

Safety Footnote You Shouldn’t Skip

This project runs on low voltage but still deserves respect. Never insert these modified “fuse lamps” into live AC mains circuits or equipment expecting actual over‑current protection—that would defeat their safety function entirely. Treat them as display elements only. Label all modified sockets clearly to prevent confusion later when someone assumes they’re functional fuses during maintenance.

The Bottom Line

The fusion (no pun intended) of reuse and creativity here captures what grassroots electronics is all about—making better use of what’s already on your bench instead of waiting for new modules to ship from overseas warehouses. Each tiny filament‑in‑fuse capsule becomes both tool and artwork—swappable indicators that cost cents yet look engineered on purpose rather than improvised messily.

Your Turn — What Would You Embed?

If you had a drawer full of spare fuse shells right now, what else could you hide inside besides filaments? Tiny sensors? Mini voltage references? Think about it—the next clever reuse might already be sitting in your parts bin waiting for a spark of imagination (and a steady hand with tweezers).

By Blog-Tec Staff — edited for clarity.

Leave a Reply