Anyone who’s ever wrestled with a set of aftermarket headers knows the phrase bad header design can become painfully real—especially when you’re lying under the car, stretching every tool in your chest just to reach that one impossible bolt. If you’ve cut an opening to drop the bolt in first and tried every swivel ratchet and extension you own but still can’t hang those headers easily, you’re not alone.

Why Some Headers Are So Hard to Install

Header installation can quickly turn into an ordeal due to tight spaces, awkward angles, or poor product design. Sometimes it feels like the engineers never had to install these themselves. Common issues include:

- Bolt holes positioned too close to bends or flanges

- Lack of clearance for standard tools

- Excessively tight fits against the engine block or frame rails

- Insufficiently slotted flanges for easy alignment

- No consideration for heat shields or wiring in the engine bay

When even specialized tools like swivel wrenches and extra-long extensions don’t help, frustration is natural.

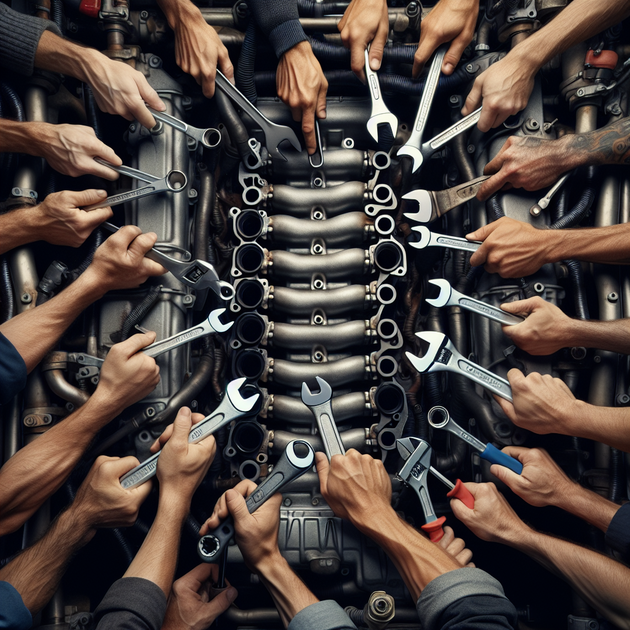

Essential Tools for Tough Header Installs

With a bad header design, sometimes factory tools just aren’t enough. Mechanics often rely on creative solutions. Consider these options:

- Universal Joint Sockets: Give more flexibility than fixed-angle swivels.

- Crowfoot Wrenches: Perfect for bolts tucked behind pipes or brackets.

- Stubby Ratchets: Great in confined engine bays where length works against you.

- Bent Wrenches: Don’t hesitate to heat and bend an old wrench—a classic trick.

- Ratchet Extensions (Wobble Type): Help snake past obstacles.

- Tape on Swivels: Wrap electrical tape around U-joints for better control.

Pro Tip:

Some techs even grind down cheap sockets to make custom ultra-thin tools. Just remember safety—wear eye protection whenever modifying tools.

Tried Everything? More Strategies from Real Mechanics

Sometimes it’s not about what you use but how you use it. Here are some strategies recommended by experienced techs:

- Thread Bolts in First: Start all bolts by hand before tightening any fully. This helps with alignment.

- Lift the Engine Slightly: Loosen mounts and jack up the engine just enough for clearance (be careful and consult guides).

- Remove Adjacent Components: Sometimes unplugging spark plug wires or moving heat shields saves hours later.

- Professional install guides from reputable sources like Hagerty offer step-by-step approaches and preparation pointers.

Anecdote: When Bending Wrenches Is the Only Way Out

A seasoned mechanic once shared his “aha!” moment after fighting a rusty exhaust manifold on an older truck for over two hours. Every tool slipped off except an old boxed-end wrench he heated up with a torch and bent into a custom shape. That single bent wrench became his go-to tool for years—not just on headers but anywhere space was tight.

Telltale Signs of Truly Bad Header Design vs. Installation Challenge

- If no combination of commercially available tools fits—even after removing nearby parts—it may be poor product engineering rather than installer error.

- A quick search of online forums or product reviews often surfaces similar complaints about certain brands or models.

- If other users consistently mention fitment headaches, chances are it’s the design at fault—not your technique.

- An otherwise highly rated set from reputable makers like Borla or Flowmaster usually means there’s a trick—or a specific tool—for that application (see Borla options at Summit Racing). Lesser-known brands may cut corners in usability to lower prices.

- If all else fails—modifying an inexpensive wrench is fair game!

Bounce-Back Question: What’s Your Worst Header Install Story?

If you’ve wrestled with a bad header design before, what finally worked for you? Do you have any secret tool tricks—or did you end up customizing your own solution? Share your experience below; someone else might need exactly that advice!

Leave a Reply