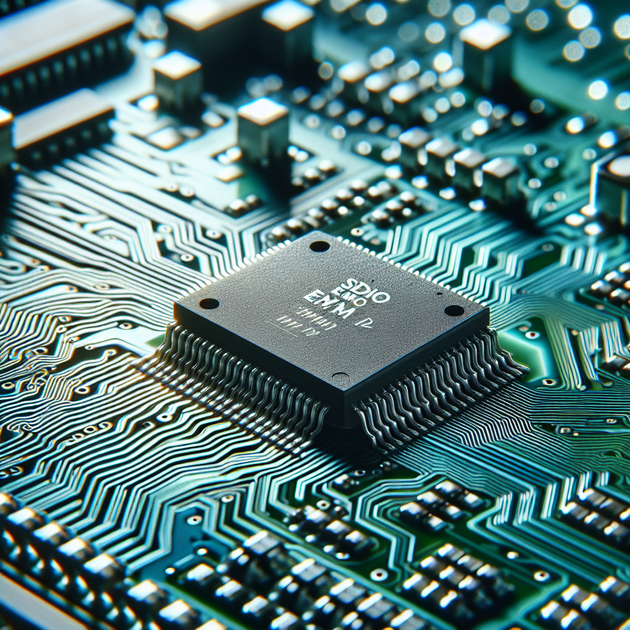

Ever looked closely at a circuit board and wondered why some of the copper traces don’t take the shortest path? Instead of straight lines, you’ll often see gentle curves and squiggles—especially near high-speed components like SDIO eMMC modules. What’s going on here? Let’s break down why designers go out of their way to make PCB traces curvy, and how these wavy lines help your devices run reliably.

What Are Curvy PCB Traces?

Printed Circuit Boards (PCBs) are the backbone of modern electronics, connecting microchips, memory modules, and other components. The thin copper paths—called traces—carry signals across the board. While it might seem logical to keep these traces as short and straight as possible, you’ll notice that some, especially those linked to memory chips like eMMC or interfaces like SDIO, have deliberate curves, wiggles, or “serpentine” shapes.

These aren’t just for aesthetics. Curvy traces are a crucial design choice, especially for high-speed signals. In fact, these patterns are so important that they have their own term in the electronics world: “length matching.”

Why Do Designers Make Traces Curvy?

The main reason for curvy traces is to match the length of other traces carrying related signals. In an SDIO eMMC module, multiple lines carry data in parallel. If one line is shorter than the others, its signal might arrive earlier. Even a tiny difference—fractions of a millimeter—can create problems at high speeds.

Here’s why length matching matters:

- Signal Timing: All data bits need to arrive at the same time. If one signal is faster due to a shorter path, you get timing errors.

- Data Corruption: Out-of-sync signals can lead to corrupted files or crashes, especially when moving lots of data quickly (as with eMMC memory).

- Interference Prevention: While length matching is the main reason for curves, careful routing can also help prevent crosstalk—where signals from one trace interfere with another—by keeping consistent spacing and reducing sharp angles.

For a deep dive on length matching, check out this straightforward explanation from PCBWay.

When Should You Use Curvy Traces?

Curvy or serpentine traces aren’t needed everywhere—only for high-speed or high-precision signals where timing is critical. Here are typical cases where these wavy paths show up:

- High-speed memory buses (like DDR, eMMC, SDIO)

- USB, HDMI, and other fast data connections

- Clocks and differential pairs that need tight synchronization

On the other hand, signals that aren’t so time-sensitive (like power or slow control lines) don’t need length matching. So, you’ll only spot these curves around the most performance-sensitive parts of a board.

Do Curvy Traces Prevent Interference?

Curvy traces themselves aren’t designed specifically to block interference between lines. Instead, preventing interference—called crosstalk—relies more on spacing between traces, careful layer stacking, and sometimes adding ground pours. Still, by ensuring signals arrive together, you reduce the risk of timing glitches that might otherwise be made worse by interference.

If you want to learn more about crosstalk and signal integrity, there’s a great overview from Altium.

Anecdote: A Real-World Lesson in Wavy Lines

A friend once built a prototype board for an SD card reader. To save time, they routed all the traces in straight lines—no curves or wiggles. The board seemed fine until files started corrupting at high speeds. After some head-scratching, we realized the data lines weren’t the same length, so signals were arriving out of sync. A quick redesign with length-matched, serpentine traces solved everything. Sometimes, a little extra copper can make all the difference!

Key Takeaways: Why Curvy Traces Matter

- Curvy traces help match signal lengths for high-speed data.

- They’re essential for timing-critical interfaces like SDIO and eMMC.

- While they don’t directly prevent interference, they’re part of good signal integrity practices.

- You’ll mostly see them on memory buses and fast data lines.

So next time you peek inside your gadgets and spot those elegant curves on a circuit board, you’ll know they’re not just for looks—they’re keeping your data safe and speedy!

What other hidden design choices have you noticed inside your favorite tech?

Leave a Reply